[fibosearch]

Guidelines

The standards and guidelines

Many of our customers are unsure which gloves to buy or which are the most important protective equipment guidelines. That’s why our team has summarized the most important information you should know about disposable gloves.

Types of disposable gloves

Disposable gloves are one of the most commonly used safety products out there. They are used in medicine, the food industry, the chemical industry, the automotive industry and photochemistry, among others. There are many things to consider when choosing a glove, including quality, protection and allergies. Below is a brief summary of the three types of gloves and their differences.

Nitrile gloves

Nitrile gloves are made from nitrile butadiene rubber, another synthetic material. They are an alternative for people with latex allergies and have a longer shelf life than latex gloves. Nitrile is three times more puncture resistant than latex, but once the glove is punctured it tears completely. Nitrile comes close to latex in fit, feel, dexterity and durability but is more resistant to oils, greases, solvents and chemicals.

Vinyle gloves

Vinyl is a synthetic, non-biodegradable, protein-free material made from polyvinyl chloride (PVC) and plasticizers. Because vinyl gloves are synthetic and non-biodegradable, they last longer than latex gloves, which often degrade over time. Vinyl gloves are very cheap to manufacture, so the gloves are very affordable to purchase. Like latex gloves, vinyl gloves come in different strengths and with or without powder.

Latex gloves

Latex, the most popular glove material, is a biodegradable material derived from the latex tubes of the rubber tree. Despite the development of synthetic materials, it is still the most elastic, durable and dimensionally stable material for gloves. This gives the wearer a high level of dexterity, tactility and comfort, making these gloves an ideal tool for medical applications, auto repairs and the food processing industry.

Intended areas of application

Medical Application / Healthcare

Industry

Beauty industry

Grocery / Gastronomy

Laboratory / General use

Cleaning / housekeeping

Possible problems

Allergens

Powdered latex gloves can cause allergic reactions. The powder absorbs allergenic substances that are thrown into the air and inhaled when the glove is removed. According to DIN EN 455, disposable medical gloves made of latex are therefore no longer permitted. Because the plasticizers in vinyl raise health concerns, nitrile is now considered the safest material.

Mazeration

The well-known phenomenon from the bathtub. This is because the fingertips swell and shrivel up due to a build-up of heat and moisture. The simplest solution for this is recommended underwear gloves made of cotton, which have to be cleaned in a disinfection washing process, especially for medical use.

Perforation

The longer a protective glove is worn or the more strenuous the activity, the lower the ability to detect any tears or holes. Therefore, it is recommended to change nitrile gloves in particular after 15 minutes at the latest or after washing the patient.

Contamination

If the perforation goes undetected or the protective gloves are removed incorrectly, there is the possibility of contamination with viruses, for example. Therefore, care should be taken to ensure correct application.

The most important standards for protective gloves and medical gloves

Personal Protective Equipment (PPE)

In contrast to or in addition to disposable gloves, items of personal protective equipment aim to protect the person wearing them from one or more hazards.

Medical device (MD)

Roughly speaking, this means products with a therapeutic or diagnostic purpose for humans. All disposable gloves mentioned and linked in this article fall into this category. In principle, it can be said that this protects other people (such as patients). The Swiss Agency for Therapeutic Products is responsible for approval and regulation in this country.

Standards: protective gloves and medical gloves

ISO EN 374

Protective gloves against chemicals and microorganisms.

Includes penetration testing using air or water tests. The result is reflected in the AQL value.

ISO EN 455

Medical gloves for single use.

The primary goal is hygiene and the prevention of infections in the doctor-patient relationship.

ISO EN 420

General requirements for protective gloves.

The aim is to protect the user. The detailed imprint is mandatory to prevent any confusion.

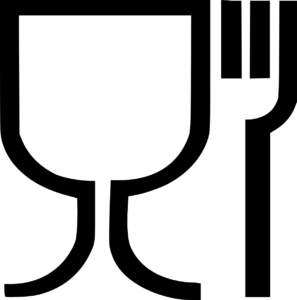

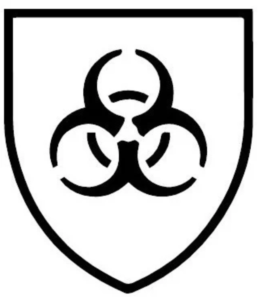

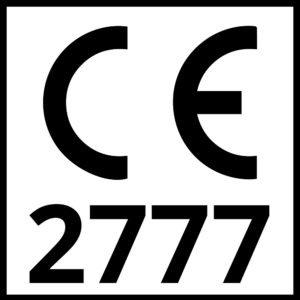

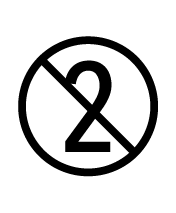

What do the symbols on the packaging of disposable gloves mean?

How can I be sure the gloves I buy are of good quality?

The standards printed on the product packaging and the corresponding pictograms provide a first indication of whether the disposable gloves actually deliver what was promised.

If there are further uncertainties about the product quality, it is worth requesting certification from the seller, looking for reports in the EU rapid alert system (RAPEX) or submitting the products to an independent testing agency for testing.

As a reminder: Directly below the printed CE certification symbol is a four-digit number that indicates the testing agency. In our case, SATRA is the test center for our gloves with the CE 2777.